Markets

Aerospace

Automotive / RV

Industrial

Marine

Specialty

Product Type

Adhesives

Heat-Resistant Thermosetting

Nitrile Rubber

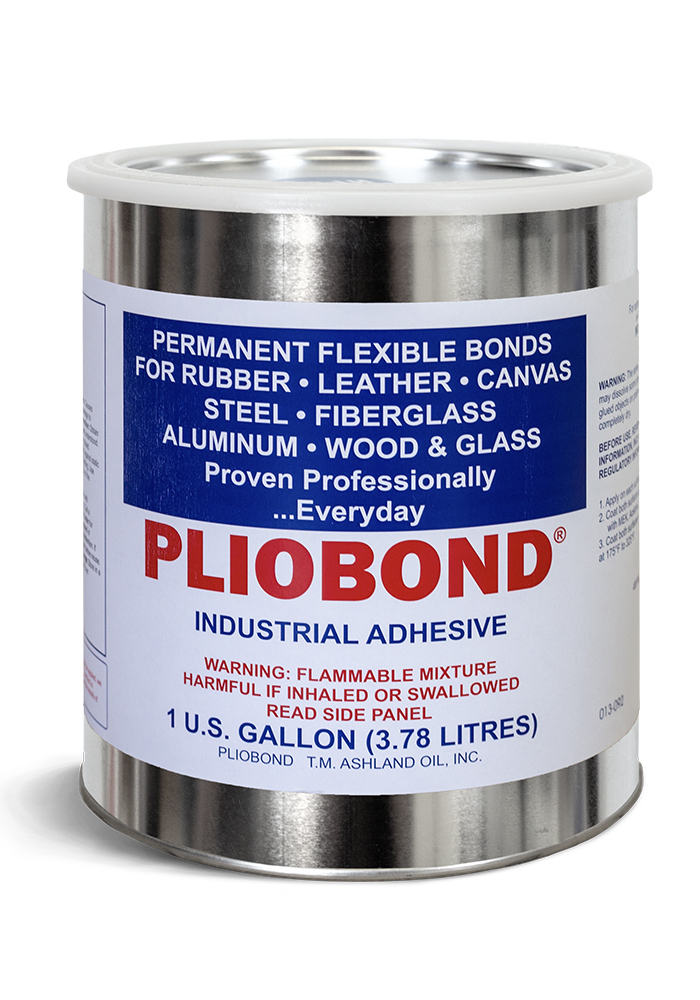

Pliobond

Applications

Thermocuring Adhesive, High temp gaskets (automotive RV)

Packaging

Pint Can, Quart Can, Gallon Can, 5 Gallon Pail, Drum

Downloads TDS SDS

Videos

Color

PLIOBOND® HT 30

PLIOBOND® HT 30 thermosetting adhesive is designed as a one-part, fast curing adhesive exhibiting good shelf life at ambient temperatures. PLIOBOND HT 30 adhesive will not cure below 300°F (149°C). PLIOBOND HT 30 adhesive cannot be used in applications requiring contact or solvent activation adhesives. At the hot-bonding temperature of 300oF suggested for PLIOBOND HT 30 adhesive becomes thermoplastic, creating an initial bond. To fully cure PLIOBOND HT 30 adhesive, continue exposure to temperatures of 300°F to 400°F (149°C to 204°C) for 15 minutes under a pressure of 50 psi for relatively soft substrates and higher pressures for good contact with harder substrates. Once cured, PLIOBOND HT 30 adhesive forms a resilient, thermo-set bond exhibiting excellent chemical and environmental resistance. The heat resistance of PLIOBOND HT 30 adhesive is demonstrated by its ability to withstand creep under a sustained load of 10 psi indefinitely at 500°F (260°C). In comparison, PLIOBOND 20, 30, 40 adhesives cured at ambient temperatures will exhibit creep under a shear load of 10 psi at 160°F (71°C).

When PLIOBOND® HT 30 adhesive is stored indoors, out of direct sunlight, and in the original, unopened container between 60°F and 80°F (16°C and 27°C), the shelf life is six months. Always rotate stock.

PLIOBOND® HT 30 adhesive contains ingredients which could be harmful if mishandled. Contact with skin and eyes should be avoided and the recommended personal protective equipment should be used.

Ruscoe maintains Safety Data Sheets on all of its products. Safety Data Sheets contain health and safety information for your development of appropriate product handling procedures to protect your employees and customers.

Our Safety Data Sheets should be read and understood by all of your supervisory personnel and employees before using our products in your facilities.

Typical Properties:

| Base | Nitrile/Phenolic | |

| Color | Tan | |

| Solids by Weight, % | 30% ±2 | |

| Solvents | MEK | |

| Viscosity, Brookfield, cps, Spindle No. 3 @ 10 rpm | 5150±1400 | |

| Specific Gravity | 0.89 | |

| Pounds per Gallon | 7.41 | |

| Flash Point (Seta Flash) | 25°F (-4°C) | |

| Estimated Coverage Rate | 150-200 sq ft/gal |